Propelling the robotics revolution with embedded robotics consulting services.

From warehouses to healthcare to delivery services, robots are augmenting traditional labor in ways only dreamed of just a few years ago. Different robots require different engineering to operate safely and efficiently. Mobile robots sense their environment, successfully navigate and must be ready for surprises — like a human coworker crossing their path. Manipulator bots must be able to safely grasp and move objects without either dropping or crushing them while also being aware of surroundings in order to avoid injury or product damage.

As an embedded robotics design firm, Cardinal Peak has helps customers with both robotic electronics hardware development and software design for robotic applications. Our team brings a unique blend of hardware, RF communications, software and IoT engineering expertise to every project, providing you with a single go-to source for unsurpassed robotic development.

Embedded Robotics Design Services FAQs

What Industries Typically Use Embedded Robotics Design Firms?

Robots are revolutionizing the way that the world works, and they are being used in many industries today. The industries embracing and being transformed by robotics are healthcare, manufacturing, and automotive, just to name a few. Cardinal Peak is experienced in embedded robotics design and has helped many customers with robotic electronics hardware development. Contact us today and find out how our robotics engineers can help you!

What are the Challenges of Software Design for Robotic Applications?

Engineering anything has its challenges, but when it comes to software design for robotic applications, there are several factors to keep in mind. The primary factor to consider is safety. What are the things that can go wrong? What are the consequences when they go wrong? How frequently will they happen? You prioritize development based on the frequency of the event and the severity of the outcome. As robotic applications involve moving, the next challenge is around location and orientation. For example, a robotic lawn mower needs to know precisely where it is relative to the flower bed while a robotic vacuum can be less accurate in its positional accuracy. Depending on the specific robotic application, orientation and location might be accomplished using a variety of sensors which could require more or less sophisticated algorithms to interpret. On one end of the spectrum are absolute position sensors such as digital encoders that don’t require much interpretation of the data. On the other end of the spectrum are sensors that require significant interpretation, such as cameras.

How Long Does Robotic Application Development Take?

There are many different factors to evaluate when estimating the length of time that a project will take to complete. First is whether the goal is to make a proof-of-concept (POC) versus a full prototype versus a production-ready minimum viable product (MVP). A second factor is whether the work requires development of custom hardware and what type of certifications (FCC, UL, CE, etc.) are needed. Will custom tooling be required for production? After that is the complexity of the embedded software. Will sophisticated AI or ML need to be developed? Once we have an initial discussion on your specific project, we can generally give a quick ROM estimate based on similar work we have done. If that ROM matches your expectations, then we can develop a full bottom’s up budget and schedule. Contact us to learn more about our services and how we can help you today!

Robotics Software & Hardware Development Related Articles

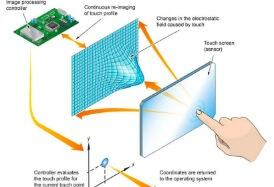

How Capacitive Touch Screens and Proximity Sensors Work

Q&A With QA — Why Cardinal Peak Implements QA at Every Step: Part I

Why is quality assurance so important? At Cardinal Peak, we engineer quality testing into each step of the engineering process to reduce uncertainty and ensure your product gets to market. Not everyone does that, but we think it’s critical.

Fostering the Future of STEM Through Mentorship — and Robots

Why is quality assurance so important? At Cardinal Peak, we engineer quality testing into each step of the engineering process to reduce uncertainty and ensure your product gets to market. Not everyone does that, but we think it’s critical.