At Cardinal Peak, we recognize the value in continuous innovation because the introduction of new ideas, processes, products or services can change companies and the industries they operate in for the better. In part one of this series of blogs, we took a look under the hood at how our partner Analog Devices A2B technology works, as well as its use in automotive applications. This post will investigate other potential applications for the A2B digital audio bus.

As an Analog Devices (ADI) design partner, we’re well versed in ADI technologies and sought to help ADI determine other applications in which people might use this technology outside of cars. Let’s take a look.

To read about the latest Analog Devices A2B release, the AD2437 chip, and a recent project, check out this post on using A2B technology for conferencing, live audio and other applications.

Contents

Using Analog Devices A2B Technology in Conferencing and Sound Reinforcement Systems

In conference room applications, minimizing background noise and focusing on the speaker presenting is of crucial importance.

With wireless audio systems, the delay creates difficulty and it’s next to impossible to do noise cancellation. However, with A2B’s bidirectional ability, each active speaker, spaced out either on a table or across a room, enables the localization of noise cancellation to reduce or eliminate background noise and deliver very clear audio. Plus, because noise canceling requires a microphone to listen, the UTP cable can chain a lot of the microphone-speaker combinations together.

Additionally, A2B technology unlocks unprecedented scalability. Once the manufacturer’s base unit is in place, the technology’s ultra-configurable nature easily enables the ability to continue chaining on additional speaker and microphone units to match the room characteristics and create a larger system — regardless of the room size.

Using A2B Technology in Control Systems

Working in electrically noisy environments, there are often remote motors or controllers removed from the main computational unit (i.e., on the end of a robotic arm), and minimizing the amount of cabling to the sensors or the motors is ideal. While alternatives can work, A2B’s two-wire twisted pair is easy to cable in a moving device/control system.

In control system applications, each sensor and controller are typically wired back to the main computational unit, which creates a larger cable. But by employing A2B technology, all of the sensor and controller lines are multiplexed onto the A2B cable, reducing the wire count and increasing the reliability. Plus, a secondary A2B wire could be used to protect the system from failure. This approach creates a single indicator that all the sensor data is present.

Using A2B Technology for Live Performances to Reduce Latency and Jitter

A2B’s deterministic low latency is extremely beneficial for stage bands. While other technologies add a delay into the system, which can make it difficult for musicians to keep in sync, with A2B, the delay between the performers is almost zero. A2B technology is also capable of transporting audio data to a significant number of audio channels, so the size of the band doesn’t place added pressure on the entire audio system. Plus, because the cabling is extremely small and light, system architecture leveraging A2B technology could help minimize the remote amplifier costs.

Utilizing A2B Technology for Digital Signal Processing (DSP) Operations

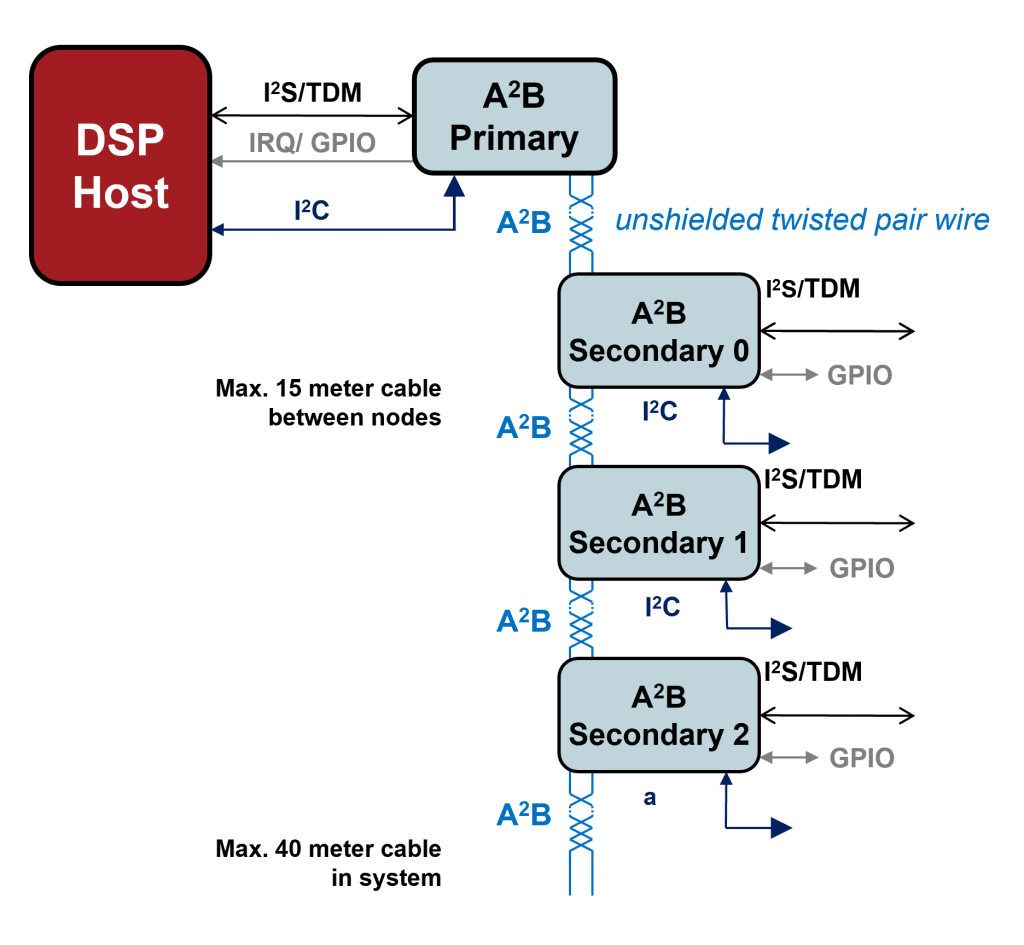

Generally speaking, the ability of a product to adapt to a larger workload without compromising performance is preferred. When utilizing A2B for digital signal processing (DSP) operations, the base unit is designed for the optimal cost of the most common configuration. However, if the DSP requirements outgrow the base unit, additional DSP nodes can simply be added on the A2B bus to scale the product up. Even better, because the technology uses the same cabling, there are no added connectors, and A2B is capable of creating a “DSP farm” for high-end applications.

Due to our deep experience in developing products featuring Analog Devices’ SHARC processors for audio products, transceivers for software-defined radios (SDRs) and A2B for automotive products, we are recognized as an ADI design partner. As such, we cannot understate the value of leveraging what ADI’s software standard is. By following their standard and porting the code to custom hardware in maintaining the ADI framework, developers can utilize a vast number of diagnostic and monitoring tools to bring the optimal product to market — even if that product falls outside the traditional scope of connected vehicle design.

Discover how Cardinal Peak applies ADI technologies across a wide range of markets and industries to deliver the best possible product — regardless of application. Contact us today to tap our trusted ADI expertise to help develop the solution that tackles your design challenges and addresses your unique needs.